Professionalism and reliability

for 140 years

look at our history and see how we have changed

look at our history and see how we have changed

I do believe that team’s spirit guided by a common vision and goals leads us to the tangible future.Yesterday we dreamed of what is already taking place at our plant today. That is why and how we accept the challenge.

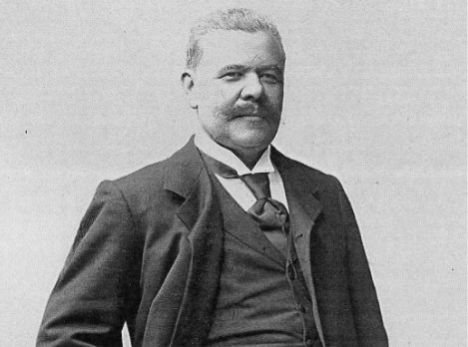

Henry Mac Garvey builds in Glinik Mariampolski a Machinery and Drilling Equipment Factory in Glinik And an Oil Refinery.

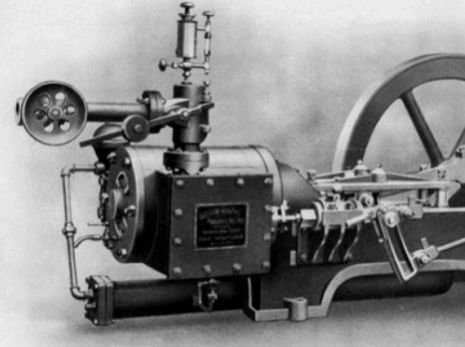

The first steam drill machine produced at the Glinik Machine and Drilling Tools Factory.

The first SM-2 drilling rig designed and manufactured by the Glinik Drilling Machines and Tools Factory.

Drilling machine Udarex

At the time, the OP-1200 drilling rig, the first units of which were made in 1957, was experiencing its renaissance.

Drilling machine Op 1200

Drilling machine Wos-2000

Since its inception, Glinik has produced various types of drilling rigs for various applications

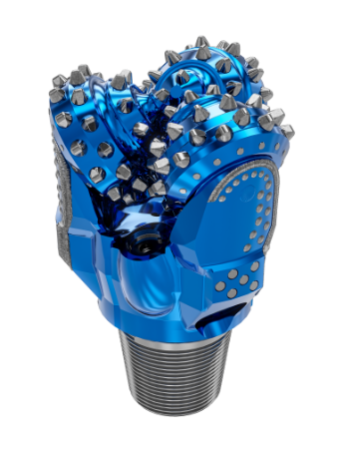

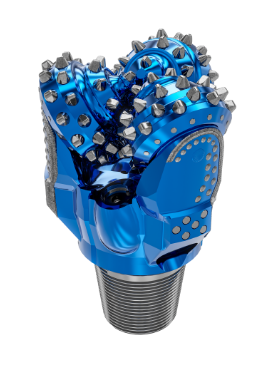

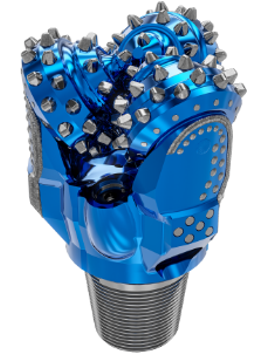

Introduced into serial production drill bits with a range from fi 216 to 308 of which the Glinik factory was the only manufacturer in the country.

1899

The first drill bit designed and manufactured by the Drilling Machines and Tools Factory.

First drill bits

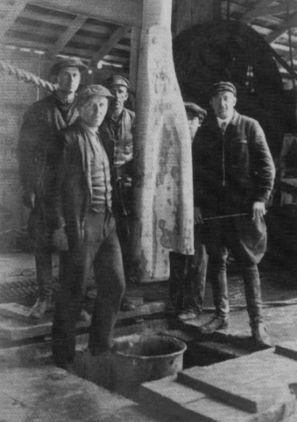

Employees of the rotary department in the production of drill bits.

1960

First drill bits.

2019

Pierwszy świder 42" wyprodukowany w Glinik

We have been developing Glinik brand by creating innovative, advanced and useful products. Our wide portfolio offers solutions for demanding Customers who appreciate the technologies provided by Glinik.

Glinik in numbers

years of legacy

countries we sell to

employees

thousand drill bits produced

Our values

We emphasise loyalty to each other and honest communication at Glinik Co. We respect diversity of views and are not afraid to make innovative changes.

We make bold and well-considered decisions at Glinik Co for which we we take full responsibility. We expect initiative from ourselves and always prioritise company in our actions.

Glinik always keeps its word and places great emphasis on reliability and honesty in our operations. We focus on fair play and ensure that we fulfil our obligations to customers, partners and employees.

There is an atmosphere of mutual trust at Glinik Co., allowing us to create a cohesive team. We rely on open dialogue and are willing to listen to others. We make decisions together and pursue goals together.

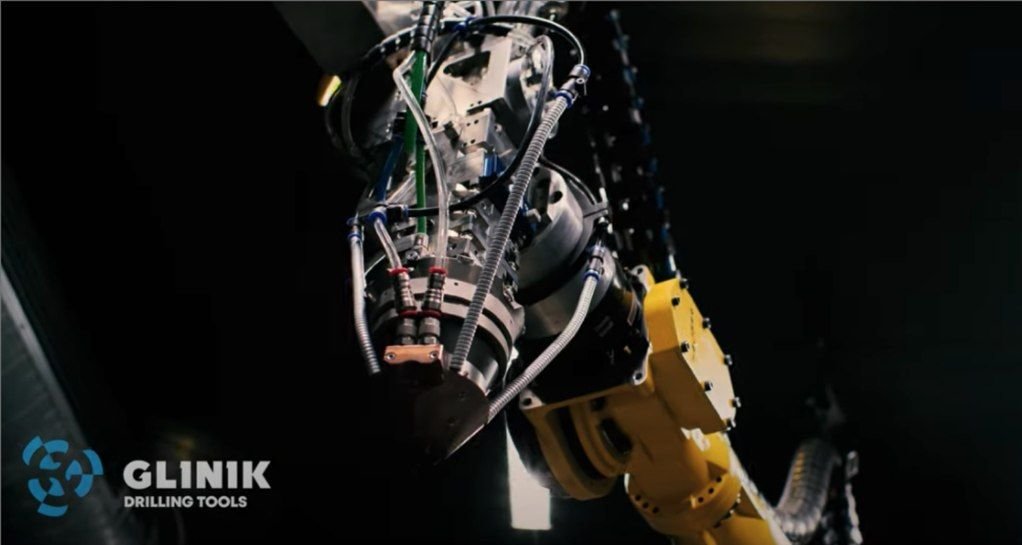

Innovation and development

Modern technologies: they are common factor in many projects, initiatives and products implemented at Glinik Co. Putting them to use is one of priorities in our development strategy for the coming years.

Quality assurance: We are API certified, which entitles us to brand our API-compliant drilling tools, stabilizers and adapters with the API monogram.

Safety of employees and work-friendly posts, as well as concern for the environment, are key values for our company. The lives and health of employees are paramount values - our every activity is directed towards ensuring their safety.

Glinik engineering staff have constantly been pursuing advanced R&D projects aimed at product development and newest hi-tec solutions implementations.

Glinik is people!

Our projects

In several pilot drilling holes and various rock formations the bit has proven top performance and minor shirttail werar. Nozzles size and cutting structure design have been properly selected to safeguard troublefree operation on site.

Once PDC bits failed to break through very demanding, abrasive formations, Glinik TCI bit was selected and did the job very well. As a result, the drilling was continued with another Glinik TCI bit to reach the final depth with the expected water temperature, which can be used for the termal pools complex. Heavy-duty, leg back protection Glinik bits with premium bearing system can be the first choice in specific geothermal drilling conditions.

Total depth achieved with one run thanks to Glinik bit with effective bearnings and premium gauge and leg back protection. Drill bit equipped in 4 jet flushing allowed for smooth, constant drilling with no bearing overheating risk and let fully avoid the bit balling. No wearing sings on hardfaced surface prove the top quaity of the materials used.

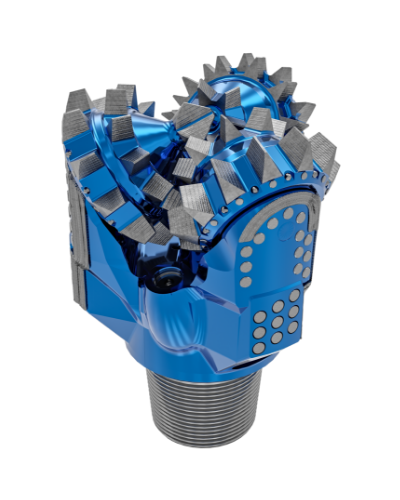

Large diameter bits designed for reverse circulation drilling in very demanding geological conditions - Kimberilite Pipes which are including the diamond deposits. The most important goal achieved was the reliability of the bits what helped to finish the project in a safe and failure-free way.

Glinik products are present in all drilling segments.

Modern drilling operations in the energy industry require tools with the highest reliability that meet high performance requirements. The answer is Glinik's innovative API-certified technology for use at maximum performance.

Glinik offers turn-key solutions for down-the-hole drilling. Our R&D influences the continuous improvement of air cooled bits for blast holes in open-pit mines.

Hydrogeological projects are currently gaining global importance. Our philosophy is to understand drilling contractors’ problems and provide reliable solutions. Keeping that in mind, Glinik has come up with optimal technology for hydrogeological drilling.

Glinik introduced drilling tools dedicated to all kinds of geotechnical works. Our solutions are perfect for all kinds of ground research works to meet the assumptions of the most demanding projects.

Glinik’s hole openers are apt to drilling long intervals and maintaining the hole trajectory due to advanced gauge protection technology.

We are building the future

Are you interested in high-quality solutions for drilling tools that work in all conditions, on all continents?

Find out more on our website